We are pioneer in manufacturing the excellent quality of the Locking Elements and also supplying to the many industries of the India and also connected broadly as the sincere Locking Element Manufacturer in India. The Manufactured Locking Elements are the most wear- and maintenance-friendly, space-saving and cost-effective design of a friction-locked shaft-hub connection. We are making the outstanding quality of the locking elements which lasts for the longer years and also provides the better functional life. Locking Elements are components manufactured to high precision tolerances and are used on shafts, to transmit torque to- or from- the shaft in a number of different ways, depending on the application. It is a device which locks the Shaft with the Hub for further manufacturing activity also included to be greatest Locking Element Supplier in India. These are meant for highly stressed Shaft Hub Connections. The Nylon Locking Element forces the threads on the opposite side of a spring-loaded device to compress against the mating threads of a tapped hole, providing the thread locking property. This compression has sometimes caused installation problems when installing into soft metals. When the steel threads of a spring plunger are forced against aluminum threads of a tapped hole, the steel threads can damage the softer aluminum threads, impeding installation or removal.

We are well thought-out to be Locking Element Gujarat as the excellent company. These locking elements are widely applied for the Shaft mounted gear units, Crane wheels, Conveyor pulleys, Mixer shafts, Pump impellers, Bucket wheels, Wind mill propellers, Drum connections for belt conveyors, Sprockets, Ship & Aircraft Propellers, Turbine rotors, Cold forming presses. Hydraulic Shrink discs are so far, mostly used in Windmill Industry, where the shaft diameters are huge.

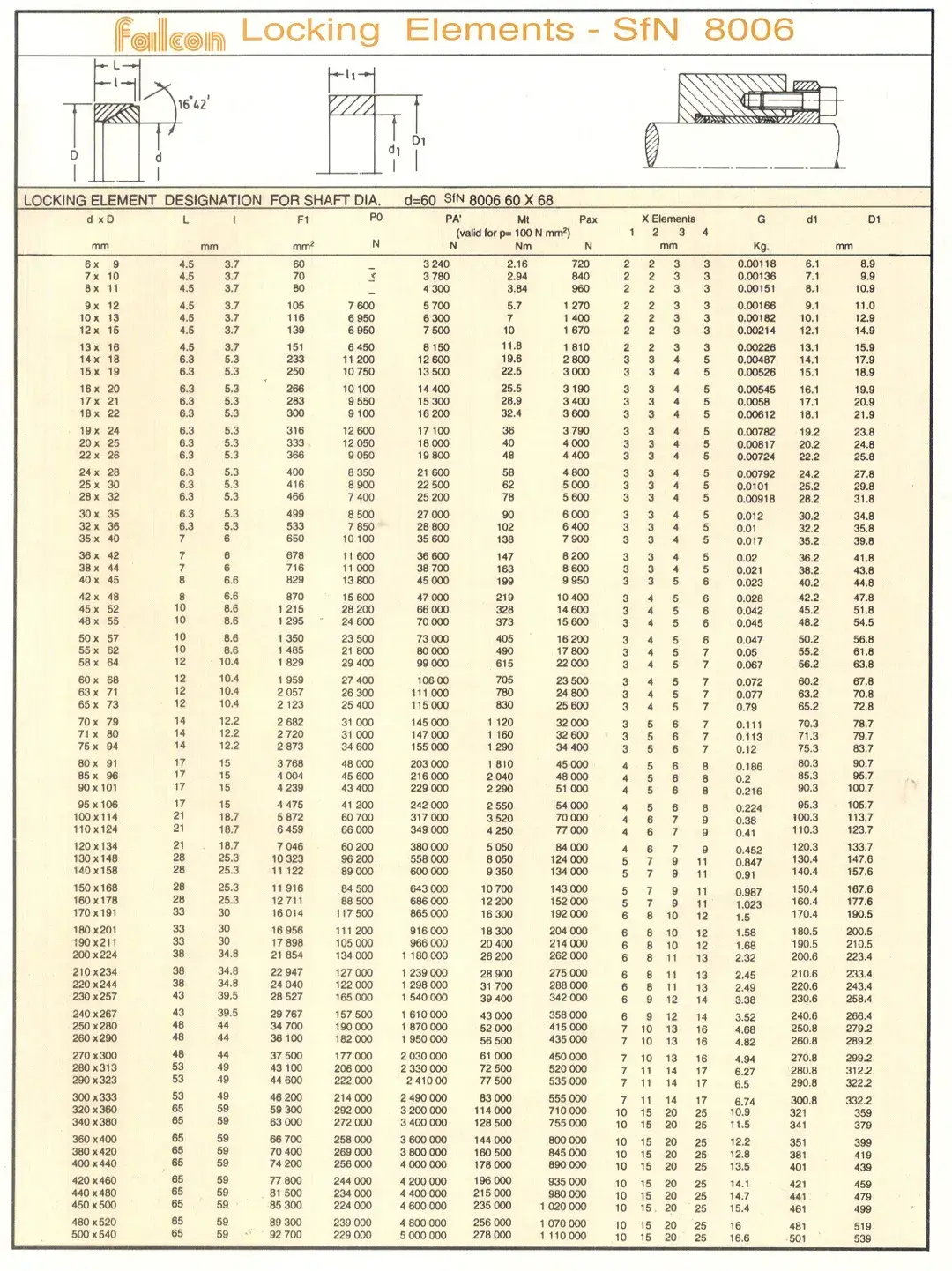

| Surface finish for shaft & hub : | Rt < 6 mm | |

|---|---|---|

| Tolerance Recomanded : up to 38 above 38 |

Shaft h6 h8 |

Hub H7 H8 |

| Friction Coefficeient : | M = 0.12 for slightly oiled Locking Elements Mtot = 0.14 for Locking Screws |

|

| General forque : Mt = 9560 P/n (Pin kw) 7026 P/n (Pin H.P.) |

Mt1 = Mt x Factor of Safety No. of elements required = Mt1/Mt (torque capacity of Elements) |

|

| -P = Power n = RPM of driven part | ||